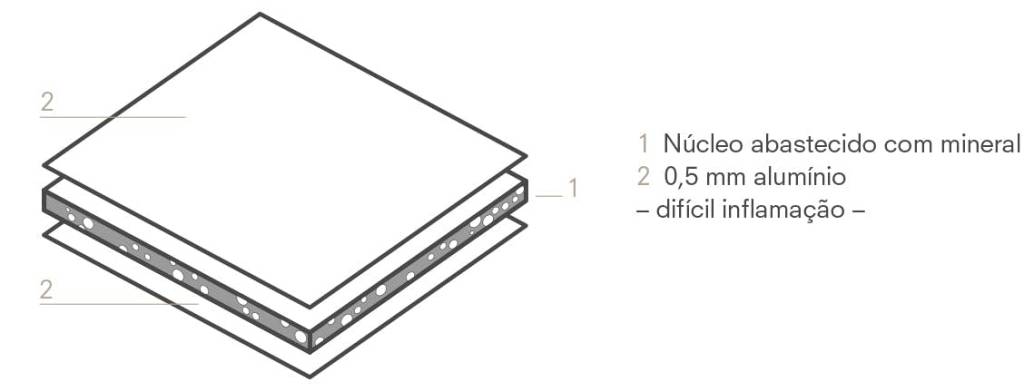

ALUCOBOND® PLUS

ALUCOBOND® PLUS is a composite panel consisting of two aluminium cover sheets and a mineral-filled polymer core. The superb properties of this material boost one’s inspiration and offer architecture a whole new range of solutions – whether your project is a private home, a public building, a corporate headquarter and offices, or a trading or industrial complex – or if your organisation wants to create a new image-building Corporate Design – whether for petrol stations, car showrooms, banks or supermarkets. ALUCOBOND® even offers a multitude of application options in the Transport & Industry sector.

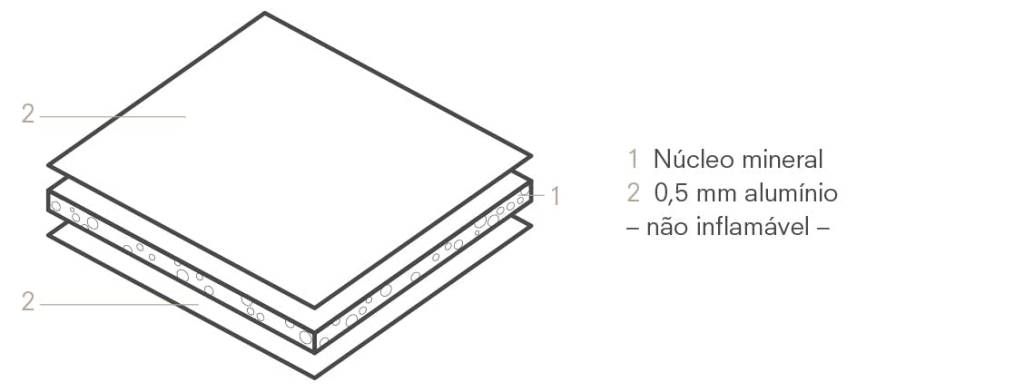

ALUCOBOND® A2

ALUCOBOND® A2 is our non-combustible aluminium composite panel used in architecture that fulfills the respective standards worldwide. Thanks to its mineral-filled core, ALUCOBOND® A2 meets the strict requirements of the fire regulations and enhances the possibilities for the concept and design of buildings. ALUCOBOND® A2, just like all the products of the ALUCOBOND® family, allows simple processing, is impact-resistant, break-proof and weatherproof and, above all, non-combustible.

ALUCORE ®

In contrast to conventional honeycomb composite panels, the system components of ALUCORE® are bonded in a continuous process. The material does not become brittle-hard but shows tough and resilient properties and excellent peel strength – the basis for a high product quality. Planners, architects and designers appreciate ALUCORE® because it combines high mechanical properties, such as the tensile strength of the cover sheets, with outstanding processing and aesthetic features.

The continuous production process allows the production of large size panels up to lengths of 9 m, with superior flatness. Clean, easily fabricated with perfect details, a great variety of applications is possible with the use of ordinary tools. Its particular characteristics make ALUCORE® the ideal choice not only for outdoor applications such as façade cladding, roofing, balconies, shelters, etc., but also for interior design like artistic ceilings, or for applications in transport and industry.

In addition to its low weight and perfect flatness, ALUCORE® shows excellent weathering resistance. With regard to the surface finishing, high-quality lacquering systems with optimum resistance to weather and industrial pollution are used exclusively.

The standard core consists of aluminium foils from AlMn alloys (EN AW 3003). Cell size B: 9,3 mm.

The cover sheets of the ALUCORE® panels consist of corrosion-resistant Peraluman alloys (AlMg1/5005A) and may be used in a decorative or functional way, depending on the purpose of application.

Structure

H: Total thickness

d1: Thickness of AL front sheet

d2: Thickness of Al back sheet

DIBOND

DIBOND® is the world-renowned brand and pioneer of composite aluminum panels. It is an aluminum composite material consisting of 2 0.3mm thick aluminum foils and a low density polyethylene solid core. The coating sheets that make up the panel – lacquered on the outside and raw or lacquered on the inside – are manufactured in continuous production. The result is a lightweight panel with excellent properties for both indoor and outdoor use. Its high strength, flexibility, optimum structural finishing of the lacquering and ease of maintenance are highly appreciated qualities.

The result is a lightweight panel with excellent properties for both indoor and outdoor use. Its high strength, flexibility, optimum structural finishing of the lacquering and ease of maintenance are highly appreciated qualities.

DIBOND® has been developed to be a more economical material, a standardized product with a more limited range of colors and sizes, destined to the Visual Communication and Interior Design markets, where the action of wind, weather or the expectation of durability, are lower than in Architecture applications.

LOCKSMITH

Aluminum, Iron, Stainless Steel and Glass.

The MNL® bets on works with a level of superior quality, namely window frames with or without thermal cut (in aluminum, stainless steel and PVC). We commercialize prestigious brand products in the national and international market, namely Domal, Hartmann, Schüco, SCA, Technal, among others.

We have a sector dedicated to aluminum equipped with machines of modern technology.

Recently MNL has implemented a production control system in the manufacturing sector according to standard N 14351-1 for the frame product and is prepared for the Community requirement of the CE marking which entered into force in February 2010.

We develop projects for both individuals and companies, betting on the quality of the materials, the trust of the service provided and the follow-up of the client in the whole process of the work.

At the same time, we work with a wide range of products in iron and steel: structures, roofs, skylights, bellows doors, swing doors, ventilation grills, lizard grills, sectional doors, industrial pavilions, supplies and assembly of all types of glass, among others.

We have a specialized team to give technical support to the project during the choice of material and during the work.

ALUCOBOND®

Discover our latest ALUCOBOND® projects now

Get inspired to create your project!